-

Tel : +8615280216342

-

Email : Lance@mosdanconcretetools.com

-

Whatsapp : +8615280216342

Tel : +8615280216342

Email : Lance@mosdanconcretetools.com

Whatsapp : +8615280216342

Mosdan PCD Tools are designed for Floor Coatings Removal.

PCD's are manufactured with a Premium Mining Grade Poly Crystalline Diamond that is unmatached in the coating removal industry. It allows PCD's to hold up under harsh conditions and continue to work when others are worn ourt.

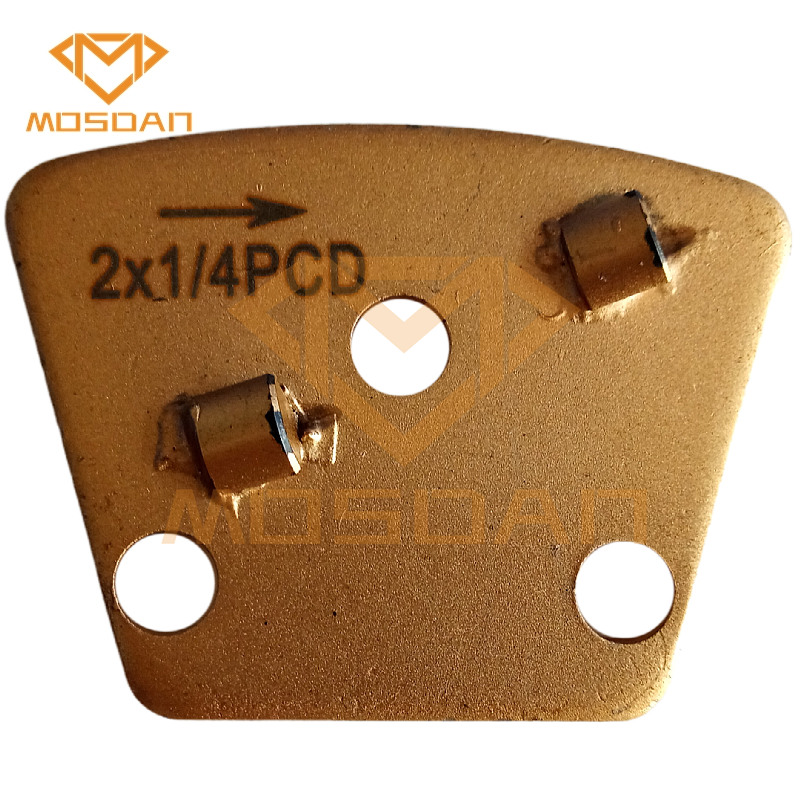

Depending on the segment size and aggressive and the PCD can be cut different sizes in 1/4, 1/3, 1/2, Split PCD Elements and 1 Full PCD with or without Sacrificial bars or metal bond buttons.

A. PCD tools without sacrificial metal bond segments are the most aggressive style and will leave a very coarse profile on the concrete underneath.

1/4PCD without metal bond segment is very ideal for removal :

-Thick mastics and glue coatings

-Thick elastomeric membranes

-1/4'' thick parking deck membranes

-30 mile and up epoxy coatings and any other coatings with silica sand broandcast mixed in

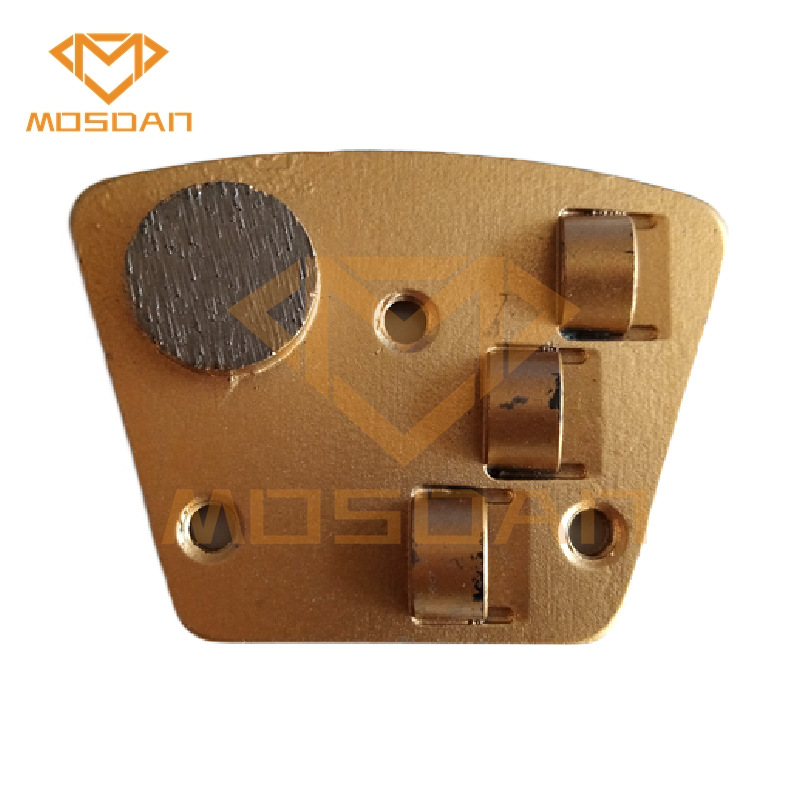

B. 1/4PCD Tools with balance metal bond bar or button are designed to remove coatings on surface like a troweled surface and will not damage the concrete. The sacrificial bar or button will be a balance function and depth guide and also protection the PCD scrapers, and reduce the gauging of the floor caused by the aggressive PCD segments. It will be ideal for the coating removal as below:

-Medium to thin mastics and glue coatings

-30 miles or less epoxy coatings.

C. 1/2PCD is less aggressive than 1/4PCD , but will be longer life because of the bigger segments size and more ideal for thin coatinsg removal.

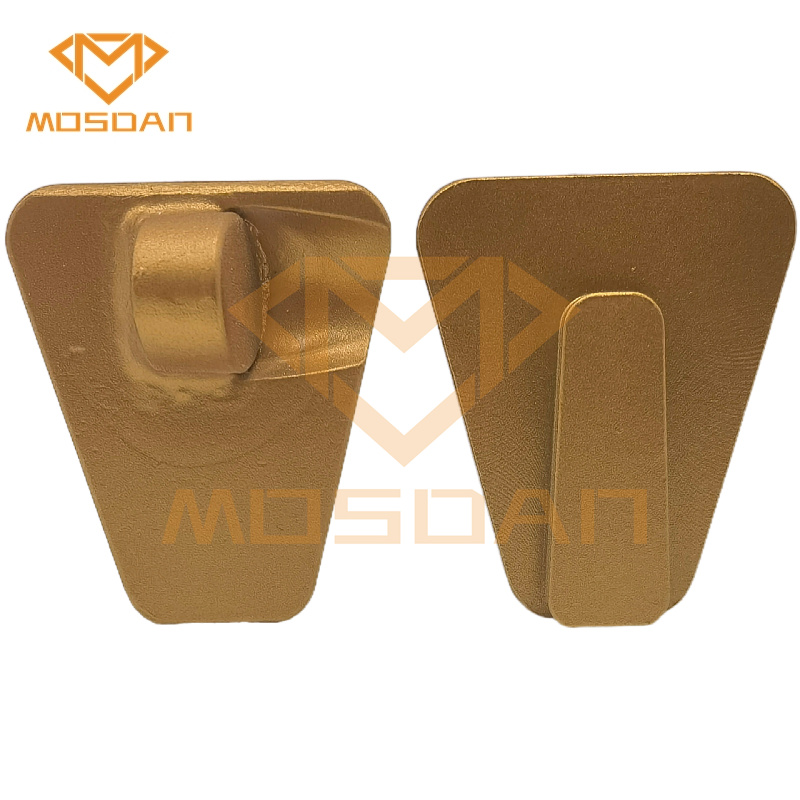

D. The Full PCD is least aggresive and sharp one, but with the longest life. It is very important that the PCD tools direction the tool plate rotation direction. It can be installed into both clockwise and counter clockwise floor grinders machines.

PCD Roation: The PCD can be made Clockwise(Right) and Anti Clockwise (Left) Direction.