-

Tel : +8615280216342

-

Email : Lance@mosdanconcretetools.com

-

Whatsapp : +8615280216342

Tel : +8615280216342

Email : Lance@mosdanconcretetools.com

Whatsapp : +8615280216342

Please kindly send us the details report as feedback, like the pictures and videos. We will analize the possible reasons and try to find a way to solve the problem. If the problem is due to the quality of Mosdan Diamond Tools product itself, we will make the compensation according to your actual loss and send you new replacement , even some payment refound, but not inclduing the shipping cost.

We guarantee ensures that every Mosdan's customer is satisfied. Any of your questions and complaint will be answered within 24 hours by our professional staffs. We are ensured that you can find help when you need it.

Please kindly let us know your order details and the shipping methods firstly.

The freight will be calculated the total weight and volume of your orders.

Choose a shipping method

Check the current freight rate and calculate shipping charges

Check the other charges and add together.

For regular daimonds orders, we need 7-10 days for production time, because of wide rang of diamond tools, not possible all of them in stock, but many semi-finished tools. Please give us time. Normally, the orders will be finished not exceed 2 weeks .

Most likely by Express, we will choose DHL, FedEx, UPS etc, it will take about 5 or 6 days from Xiamen, China to your warehouse.

If large orders, we also choose by sea and by air.

Mosdan support to pay by T/T and Paypal.

We don't offer FREE SAMPLES , according to our many years' experience , we think when people get the samples by paying, they will cherish what they get. Also thought the quatity of smaple how its cost is gigher than normal production.

Mosdan produces wide range of diamond tools and also specifications, too many pieces. That's why we don't have a price list on our website. If you would like to know our diamond toolings prices, please kindly contact us and let us know the diamond tools items and specification you wanted, we will offer you the prices as soon as possible upon receipt of your inquiry.

Mosdan is a professional diamond tools manufacturer with over 15 years of Service and support to the Diamond Grinding, Polishing and Cutting Tools, such as Metal Bond Diamond Tools, Diamond Grinding Disc, Metal Bond Grinding Plate, PCD Segments, Cup Wheels, Bush Hammer, Diamond Saw Blades, Abrasive Brush, Core Drill Bits, Dust Shroud etc toolings for HTC, Husqvarna, STI, Lavina, Terrco, Scanamaskin, Diamatic, Werkmaster, Sase, ASL,Diamatic, Newgrind, Klindex etc floor grinders and Hilti, Makita, Metabo, Bosch, Floorex etc various hand grinders.

Please place a very small trial order, then you will know our diamond tools quality clearly. At present, so many people in the world like to use Chinese products as the good quality quality with very competitive prices. We are professional manufacturer in Diamond Grinding, Polishing and Cutting Tools for concrete, stone and terrazzo since 2008, especially in concrete industry.

Mosdan would like to inform who are using our products and how our diamond work performance. If the market in your area is completed new for us. A small trial order for testing will be very necessary.

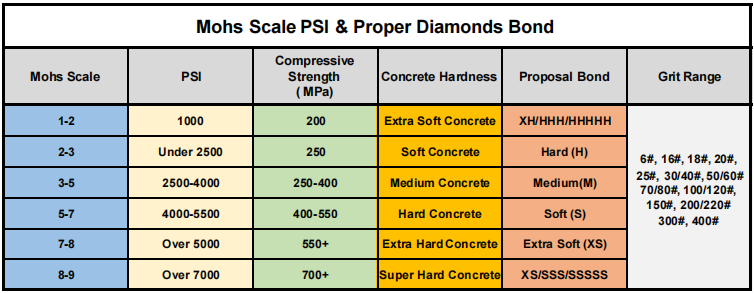

Mosdan Diamond Tools produces many bonds for different hard concrete floor.

Extremely Super Soft Bond is for Extremely Super Hard Concrete Floor

Super Soft Bond is for Super Hard Concrete Floor

Extra Soft Bond is for Extra Hard Concrete Floor

Soft Bond is for Hard Concrete Floor

Medium Bond is for Medium Hard Concrte floor

Hard Bond is for Soft Concrete

Extra Hard Bond is for Extra Soft Concrete

Super Hard is for Super Soft Concrete Floor

How to polish the SOFT Concrete Floor ?

Metal Bond Diamond Toolings Grinding Steps:

1. Choose Grit 30/40# hard bond metal grinding segment to open the concrete

2. Hard bond metal 60/80# for the further grinding and will produce the scraches on the concrete surface.

3. Hard Bond 100/120# metal grinding disc are usually the last steps for concrete floor finest preparation.

4. Hard Bond 150# (Spray Densifier )

Polishing Pads Polishing Process.

1. 100# resin bond ,hybrid or ceramic polishing pads

2. 200# resin, hyrbid and ceramic diamond polishing pads (Spray Densifier)

3. Resin 400# further polishing

4. 800# resin polishing pads polishing

5. 1500# resin polishing pads (then use sealers )

After 1500# resins polishing will be gloss meter 60-70.

6. If still need more shine, choose grit 3000# resins or burnishing pads .